Presence Tracking

Presence tracking is a feature of the Operator Client where a product blocking a PE on the server is translated to a simulated product being created in the client view in the same location. The product is created with the length that is calculated from the duration the PE remains blocked.

Note that the orientation of the product on the conveyor is not simulated (e.g. a product placed askew on the server conveyor will be shown aligned to the conveyor on the client).

Presence Tracking can be enabled on a project by enabling the Presence Tracking feature on the equipment and enabling a PLC connection and IOs to control this.

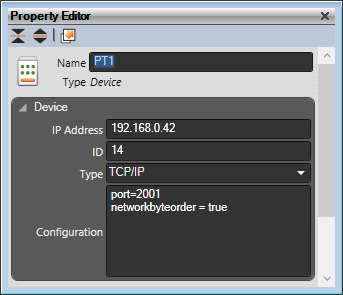

Create a device to receive the Presence Tracking messages from the PLC

- New Device and give it a name e.g. PT1

- Set the PLC IP address, port (default 2001) and networkByteOder = true

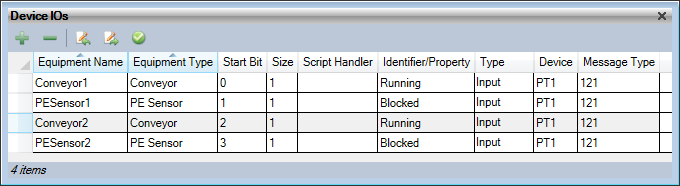

Create the required Device IO entries

- Open Device IOs manager

- For each conveyor and PE at the end of the conveyor create the entries (in this example there are 2 conveyors and 2 PEs);

The PLC Engineer will need to provide the Start bit value as it needs to be populated correctly in the PLC message block.

The equipment that supports Presence Tracking is:

- Chutes

- Conveyors

- Cross Belt Sorters

- Tilt Tray Sorters

The Presence Tracking option for the equipment is only available in the Operator Editor and can not be enabled or disabled from Integrator.

If you have opened an Operator project in Integrator the Presence Tracking may still be enabled and causes PEs to fail to block when a product passes them or product to disappear from conveyors. To disable Presence Tracking on a project, execute the macro below;

var array = Project.Equipment.Conveyors

for (var i=0; i<array.Count; i++) {

array[i].TrackingMode = BCS.Sym3.Equipment.TrackingMode.None

}

print("Done");

Enable Presence Tracking on the equipment

Select the equipment so that the properties are displayed in the Property panel.

From the Tracking Mode property select the option Presence.

For Chutes and Conveyors you may need to set the additional properties:

- PEs Not Tracking: Default = All PEs Track

Can select any PEs on the Conveyor that do NOT track. - Tracking Window: Chutes Default = 0.6, Conveyors Default = 0.8

Specify the distance in the units chosen when the project was created (metres or feet) around the PE over which the tracking is monitored. Can be from 0.2 to 2.0 metres. - Adjustment Value (Conveyors only): Default = 0.025

Can be a value from 0 to 1000.