Equipment: Product Schedule

|

|

Description

The Product Schedule component is used to create products on the conveyors listed in the Entry Components. If multiple entry conveyors are specified, the product schedule will create products on each conveyor round robin style (1, 2, 3, 1, 2, 3, 1 etc.). The Entry Components list can also have the equipments handled by other logical processor.

Creation

Simply drag and drop a Product Schedule from the Toolbox into the simulation.

Access

From the Equipment > Product Schedule

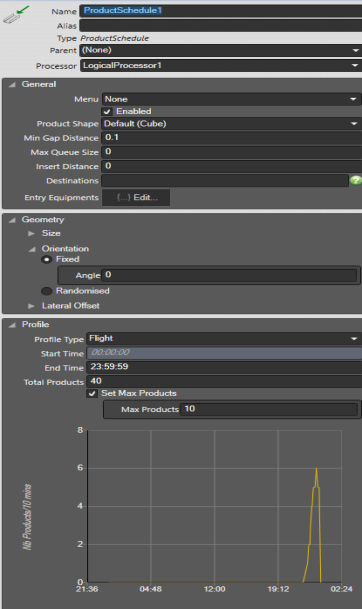

Properties

Only underlined properties below can be imported from a spreadsheet.

| Name | Description |

|---|---|

| Name | Name of the schedule. |

| Entry Equipments | List of Conveyors or Chutes where the products are created. |

| Start Time | Time when the product schedule starts. |

| End Time | Time when the product schedule ends. |

| Enabled | If unticked, the product schedule does not deliver products. |

| Total Products | Number of products that the schedule attempts to create. Note: for a Uniform schedule, the entry is in Product per Minute. |

| Processor | Logical processor where all the event handling and processing will be done for current product schedule. But it can induct products on equipments processed by other logical processor. |

| Orientation |

|

| Product Shape | Default = Cube. Allows the selection of a previously loaded Product Shape. Product moved to this schedule will not acquire this shape from the schedule but will retain the shape it was created with. |

| Destinations | List of destinations assigned to the created products. Separate the numbers by a comma for a list or a “-” dash to assign a range of numbers. Note that if no destinations are defined then products will be assigned -1 as a destination. |

| Min. Gap Distance | The minimal distance (in metres) between two consecutive products. |

| Max Queue Size | Specify a limit the size of the queue to avoid infinite queues growing. If the number of products in this queue has reached this value, any product that should be created according to the schedule is discarded (not created), so the total amount of products created may not exceed the value of Max Queue Size specified in the product schedule. The default value for Max Queue Size is zero (no queue). |

| Insert Distance | Product insert distance (in metres) on the transport. If insert distance is greater than the transport length, product will be inserted at 0 distance. |

| Length, Width, Height, Min/Max | Min and Max dimensions (in metres) for the products created. e.g. 0.6 is 60cm. |

| Min Lateral Offset | Minimum lateral offset assigned to the product. Default = 0. |

| Max Lateral Offset | Maximum lateral offset assigned to the product. Default = 0. |

| Ensure Product Fit Equipment | If ticked, will ensure that the product fit the equipment after assigning a random lateral value. Default = unticked |

| Set Max Products | If ticked, Product schedule will only generate number of products provided in Max products property. Default = unticked |

| Max Products | Maximum products to be generated when Set Max Products is ‘checked’. The product counter will reset when schedule is re-enabled or when Set Max Product is re-checked. |

| Mass | The mass of the generated product, in kilograms. Default = one. Only affects the products on physics equipment. Must be greater than zero. |

| Friction | The friction value of the generated product, 10.0 being most friction and 0.0 being no friction. |

Queues

Each product schedule as a Queue. When a product cannot be placed on the entry conveyor(s) because it is full, the product is placed in the queue. Once the product is in the queue, it will be inserted as soon as possible when a gap becomes available. It is possible to monitor the queue size in a report.

The property Max Queue Size allows you to limit the size of the queue to avoid infinite queues growing. If the queue as reached its maximum size, any product that should be created according to the schedule is discarded (not created), so the total amount of products created may not be equal to the amount specified in the product schedule. The default value for Max Queue Size is zero (no queue).

Example: a schedule creates 1 product every 5 seconds on 2 conveyors A and B. if both A and B are “free”, 1 product will be created on each conveyor every 10 seconds. If A is occupied, the schedule will only create products on B every 5 seconds. If both A and B are busy, the queue will keep increasing (by 1 every 5 seconds) and will attempts to place products on A or B as soon as possible.

In System Time (queued) includes the time when the product was in the queue, whereas In System Time (Inducted) calculates the In System time of a product from the time it was first inducted in the system.

A product schedule has a start and an end time, they create the number of products between the start and end time.

If the queue is not empty at End Time, the product schedule will keep running to empty the queue after End time.

A list of Destinations can be configured. The destinations can then be used in Rules to determine which products are pushed. If several destinations are configured, they will be assigned to products round robin style (1, 2, 3, 1, 2, 3, 1, etc.).

There are three types of Product Schedule:

- Uniform: uniform profile with constant number of products per minute

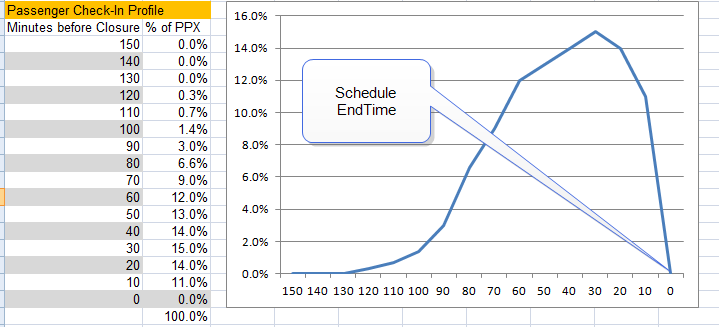

- Flight: a predefined profile based on a typical airport check-in profile.

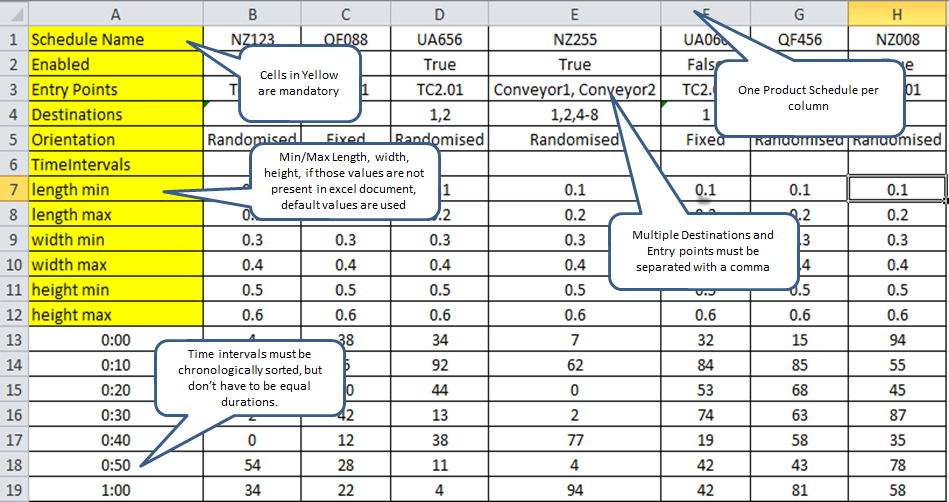

- Custom: a completely custom profile, imported from a MS Excel® spreadsheet. See “How To Import Product Schedules”

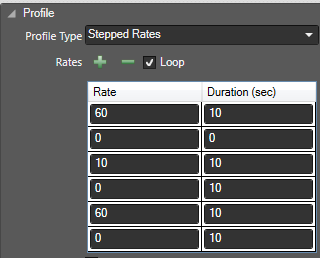

- Stepped Rates: a collection of multiple product rates (per minute) with duration(seconds). The rates will be repeated continuously when Loop check box is checked

Import Product Schedules

It is possible to import custom Product Schedules from MS Excel®.

Go to Ribbon Project > Import and click Product Schedules.

Select the Excel file and click OK.

Note: Close the file in MS Excel before the import to avoid conflicts.

Once a spreadsheet has been imported, subsequent imports of the same spreadsheet will not update any new settings it contains. To avoid this you should select the schedules to be updated and delete them.

Note: Any Reports defined on the Product Schedule you delete will no longer be linked even though it uses the same name as the imported Product Schedule. You will need to edit these reports to link them back to the Product Schedule.