Equipment: Conveyor

|

|

Description

A Conveyor transports products at their speed. They have multiple operational mode that determine their behaviour during the simulation.

All conveyors are Running by default, and use the Cascade operation mode.

Conveyors can be Straight, Curve, FreeForm or Skew.

Products reaching the end of a conveyor are removed from the simulation.

Creation

From the Toolbox, simply drag and drop a Conveyor into the simulation.

Access

From the Project Explorer > Equipment > Conveyor.

Or directly by clicking on the conveyor in the simulation.

Conveyor Operation Modes

Manual

Does what the user manually does, using actions or changing properties.

Cascade

- Only works if at least one PE Sensor is on the conveyor.

- If the next conveyor is stopped or there is no next conveyor, stops when product crosses the last PE sensor.

- If a product is after the last PE Sensor, the conveyor won’t stop until another product crosses the PE Sensor.

- Starts again when next conveyor starts again after a Start Delay. (in milliseconds)

- If the conveyor is in reverse mode, same behavior apply.

- If the conveyor is manually stopped, it will restart when the next conveyor is started or stop/started.

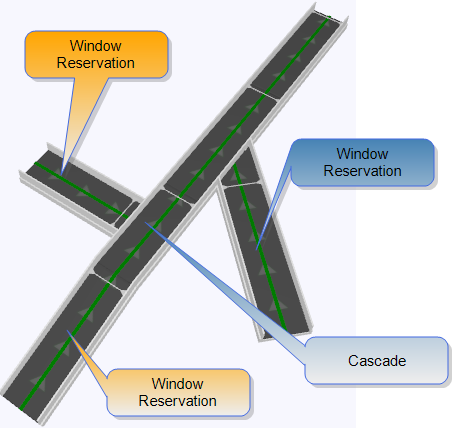

Window Reservation

This mode is to be used to make a conveyor reserve windows into their destinations Conveyor and injecting products into the windows.

- When product crosses the last PE Sensor on source Conveyor, the Conveyor looks for a ‘window’ on the destination Conveyor.

- The window size is either specified (Fixed Window Length property) or if Is Fixed Window is false, the window is equal to the product length.

- If required, the Conveyor stops when the product blocks the PE Sensor and starts to insert product in the middle of the window.

- If no window is available, product waits until a window is available.

- If the target conveyor is stopped, products will wait at the PE even if window is available. Conveyor start and induct product as soon as target conveyor starts again.

- If there are two or more products waiting for a window and the Priority of a conveyor is higher than the priority of another conveyor (bigger number means higher priority) feeding into the same conveyor, the higher priority conveyor will take over windows already reserved by the other conveyor.

All conveyors feeding into a common conveyor must be configured as Window Reservation to avoid product overlap.

Merge Target as been removed, only the merging conveyor needs to be set to ‘Window Reservation’.

ScreeningStation

- When product arrives at PE, stop for $clearance_time seconds, then start again. The product receives a status of ‘Cleared’.

Inductor

- Used to induct products on a sorter (cross-belt or tilt tray).

- When a product arrives at PE, stop the product and induct on the next available window. (See “Cross Belt Sorter”)

Properties

| Name | Description |

|---|---|

| Conveyor Type | Can be:

|

| Enable Acceleration | Default = off Enables the option to ramp up or down the speed of the Conveyor when it is started or stopped with the Start/StopRequest option. This feature can only be applied to a Conveyor in Manual mode (The fields will display but can not be changed and will not be respected). If a new speed is set before the ramping is complete then the Conveyor does not ramp to the new speed but is immediately set to the new speed. |

When Acceleration is enabled

| Name | Description |

|---|---|

| Start/Stop Request | Default = on Use this option to Start or Stop the conveyor using the acceleration/deceleration values. When enabled, the Conveyor will use the acceleration values starting the Conveyor. When disabled the Conveyor will use the deceleration values when stopping the Conveyor. |

| Mode | Default = ‘Use Time (in seconds)’ Allows the selection of the acceleration time in Speed/Time in the units chosen when the project was created (metres or feet) or a simple time in seconds to reach the speed. The Mode setting affects both Acceleration and Deceleration. The default value for the time is calculated as speed (1.3)/acceleration. (3.33) |

| Acceleration | Default = 3.33m/s2 (10.92f/s2) The acceleration speed in the units chosen when the project was created (metres or feet) per second squared. |

| Deceleration | Default = 3.33m/s2 (10.92f/s2) The deceleration speed in the units chosen when the project was created (metres or feet) per second squared. Note that when Acceleration is enabled, the ‘OnConveyorSpeedChange’ event is triggered when either the target speed is reached or the speed changes direction (stopping before start speed achieved). Settings to gradually accelerate a Conveyor; Running = disabled. The conveyor begins accelerating when Start/StopRequest is enabled. Settings to gradually decelerate a Conveyor; Running = enabled. The Conveyor begins decelerating when Start/StopRequest is disabled. To have a Conveyor accelerate on simulation start you need to set the Conveyor properties manually each time. |

| Target Speed | For acceleration improvement, a new property: “Target Speed” for conveyors has been added. Here are some description for it:

|

| Accumulate | Default = off Set the Conveyor to accumulate product (pack product end to end, behaving as a chute) when the destination conveyor is stopped. This feature can only be applied to a Conveyor in Manual mode. A useful feature of this mode is that a Product Schedule placing product on an accumulating conveyor will only place product on the conveyor when there is sufficient space to place it. |

| Keep Product Orientation After Transfer | Allow Product orientation to be maintained. |

| Enable Encoder | To enable calculation for distance travelled by current transporter. |

| Max Value | Only visible when Encoder is enabled. Max value for distance travelled by current transporter, when transporter reaches to max value, distance travelled counter will restart from 0. |

| Default Speed | The default Conveyor speed in the units chosen when the project was created (metres or feet) per second. |

Designer/Integrator ONLY

| Name | Description |

|---|---|

| Current Speed | The current Conveyor speed (if changed during simulation) in the units chosen when the project was created (metres or feet) per second. Note that if the speed of the Conveyor differs from the source or destination then you should enable either the Metering or Indexing option and specify a Gap. This avoids overlapping products. |

| Belt Direction | Default = 30 (degrees) Angle of the belt in degrees used for Skew Type. For this type, product will laterally travel on the conveyor (positive angle is to right hand side). Once the product reaches the side panel it will continue to travel along the side panel. When the product leaves the conveyor, the lateral offset of the product is kept. Value has to be between -90 degrees and +90 degrees (not included). |

| Product Count | Read-only count of Products on the selected Conveyor (click on Conveyor to refresh). |

Operator ONLY

| Name | Description |

|---|---|

| Tracking Mode | Default = None Allows selection of None, Product or Presence. |

| PEs NotTracking | Default = All PEs Track Can select any PEs on the Conveyor that do NOT track. |

| Tracking Window | Default = 0.6 (metres) Specify the distance in the units chosen when the project was created (metres or feet) around the PE over which the tracking is monitored. Can be from 0.2 to 2.0 metres. |

| Adjustment Value | Default = 0.025 Can be a value from 0 to 1000. |

| Sample Rate | Default = 0 Set the rate at which the Tracking is updated. Can be a value from 0 to 2147483647. |

Operation Mode: Manual

No properties in this mode, conveyor is controlled manually.

Operation Mode: Screening Station

| Name | Description |

|---|---|

| Clearance Time | Default = 10 (seconds) Clearance Time used by Screening Station Controller. Determines how long the Conveyor stops at each product to perform screening. Once screened the product state is set to Cleared. |

Operation Mode: Cascade

When merging in cascade mode, the Conveyor ’looks ahead’ a fixed distance for a merge ‘window’. When multiple Cascade merge Conveyors are used the ‘window’ goes to the closest Conveyor.

| Name | Description |

|---|---|

| Start Delay | Default = 500 (milliseconds) Cascade start offset after the next conveyor starts. |

| Indexing | Default = disabled Allows product to ‘index’ along the Conveyor separated by the Indexing Gap distance. |

| Indexing Gap | Separation distance in the units chosen when the project was created. (metres or feet) |

| Metering | Default = disabled Only available in Cascade mode, this Conveyor will stop/start to ensure that the head-to-head or head-to-tail gap is the minimum gap distance specified from the last PE Sensor on this Conveyor. |

| Use Head To Head | Default = enabled If true and Metering is true, Conveyor will stop/start to ensure Min Gap distance between product heads. |

| Min Gap | Default = 1 (metres) Separation distance in the units chosen when the project was created. (metres or feet) |

| Use Head To Tail | Default = disabled If true and Metering is true, Conveyor will stop/start to ensure Min Gap distance between products from tail of the leading product to head of the following product. |

| Min Gap | Default = 0 (metres) Separation distance in the units chosen when the project was created. (metres or feet) |

Notes on metering: A Conveyor set with metering applies the metering when the product is moved to the next Conveyor. Metering will only be accurate if the distance of the end PE is less than or equal to half the size of the smallest product. e.g. if your smallest product is 300mm then the PE must be set 150mm from the end.

Operation Mode: Window Reservation

When Window Reservation mode is used on a source Conveyor, it will only transfer product to the destination Conveyor when there is a gap greater than or equal to the product length (or the Fixed Window Length if Fixed Window is enabled).

| Name | Description |

|---|---|

| Priority | integer. Used for Merging Conveyor (source). Higher number means higher priority. Applied when two source Conveyors compete for the same window. |

| Fixed Window | If enabled, only a window greater than or equal to the length specified in Fixed Window Length will be reserved. |

| Fixed Window Length | Length of the window reservation, if Is Fixed Window set to true. Length is in the units chosen when the project was created. (metres or feet) |

Operation Mode: Inductor

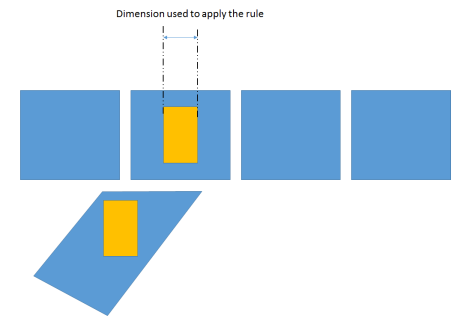

This Conveyor is placing product on a Sorter and will behave accordingly.You can apply Product width Rules when selecting an inductor mode.

| Name | Description |

|---|---|

| Apply Rule | If the checkbox is ticked then Product Width Rules are applied. |

| Small Min | It defines the minimum width size of the Product and the product will be treated as small.Default value is 0.1m. |

| Medium Min | It defines the minimum width size of the Product and the product will be treated as Medium.Default value is 0.561m. |

| Large Min | It defines the minimum width size of the Product and the product will be treated as Large.Default value is 0.721m. |

| Large Max | It defines the maximum width size of the Product and the product will be treated as Large.Default value is 0.8m. |

Validation Rules:

- If product more than large max : no induction, product stops for ever.

- If product less than small min: no induction. Product stops for ever at PE on inductor.

Size

| Name | Description |

|---|---|

| Size/Height (all types) | Height of the Conveyor in the units chosen when the project was created. (metres or feet) |

| Size/Width (all types) | Width of the Conveyor |

| Side Panel Height | Default = 0.3 (metres) Height in the units chosen when the project was created (metres or feet) of the Side Panel. |

| Side Panel Width | Default = 0.04 (metres) Width in the units chosen when the project was created (metres or feet) of the Side Panel. |

| Cut-off Angle Begin | Default = 0 (metres) Angle in degrees of the beginning edge of the Conveyor. Not available for Skew type. |

| Cut-off Angle End | Default = 0 (metres) Angle in degrees of the ending edge of the Conveyor. Not available for Skew type. |