Equipment: Tilt Tray Sorter

|

|

Description

Tilt Tray Sorters transport products on trays traveling along a path.

A Tilt Tray Sorter is configured to tilt products at exit point using Divert Rules for each exit point. The user can then entirely customize which products are pushed on each exit point independently.

Products are inducted to a sorter from a conveyor with Operational Mode set to “Inductor”.

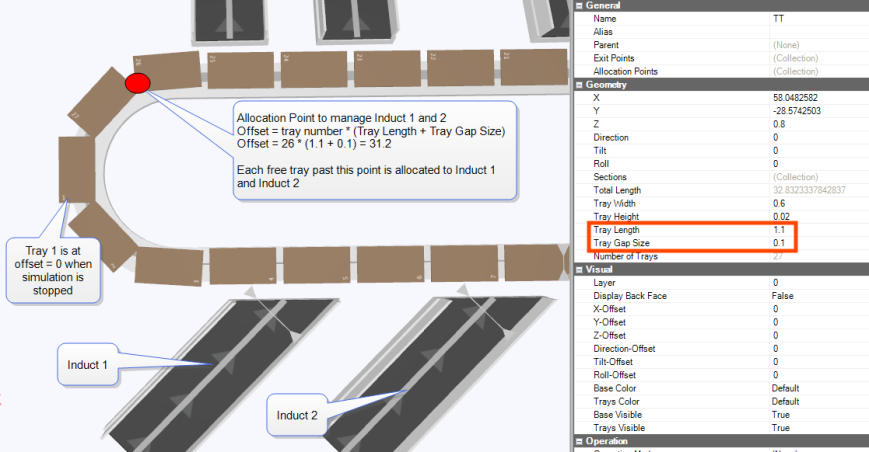

If Allocation Points are present on the sorter, trays are reserved for specific inductions as they pass by the Allocation points. Inductions managed by an allocation point can only induct products on trays reserved for itself or inductions that are upstream. For example:

- Allocation point manages 3 induction A, B and C, with A being the most upstream induction: each free tray passing by the allocation point will be assigned to A, B and C in round robin style: A, B, C, A, B etc.

If A doesn’t use a tray, this tray is usable by B or C, and if B doesn’t use a tray, the tray is usable by C.

Large products: if a product apparent width along the induction path is larger than the oversize threshold in % (e.g. 0.9 = 90%), the allocation point will book the first available two consecutive trays for this induction, and the product will be inducted at the center of the two trays. If the product apparent width is larger than the tray length + oversize threshold, the product will not be inducted at all.

Creation

From the Toolbox, simply drag and drop a Tilt Tray Sorter into the simulation.

Access

From the Project Explorer > Equipments > Tilt Tray Sorter.

Or directly by clicking on the Tilt Tray Sorter in the simulation.

Configure Exit Points

- Select the sorter and display its properties.

- For the property Exit Point, click on “Edit Exit Points”.

- The left panel lists all existing exit points. The right panel displays the properties of each exit point.

- To add a new exit point, click Add, then select the exit point

- In the left panel, select the exit chute or Conveyor, and select the Divert Rule that is used at this exit point.

Configure Allocation Points

- Select the sorter and display its properties.

- For the property Allocation Point, click on “Edit Allocation Points”.

- For each group of inductions, add one allocation point:

- Click Add

- Offset: Locate the tray number at the allocation point location when the simulation is stopped. The allocation point should be after the last chute and before the first induction. The offset of the allocation point can be calculated by multiplying the tray number by the pitch between trays (= tray length + tray gap).

- Inductions: Click …, then select the induction conveyors that are managed by the allocation point.

Chute Full

When a chute property Full is true, the sorter won’t tilt products into the chute regardless of the divert rule evaluation result.

Properties

| Name | Description |

|---|---|

| Name | The unique name for this equipment. Default = TiltTraySorterX where X is the next incremental number of Tilt TraySorters. |

| Alias | Free form text for an Alias name for this equipment. |

| Type | Read only type identifier. Always Tilt Tray Sorter. |

| Parent | The Parent equipment this is ‘attached’ to. |

| Running | Default = 2 Check box showing the running state and allowing the Sorter to be stopped or started manually. |

| Speed | The speed of the transporter in the units chosen when the project was created (metres or feet)/ second. |

| Tilt Speed | Default = 240 (degrees/sec) The speed the trays tilt at (degrees/sec). e.g. 0.5 second to tilt 120 degrees. |

| Oversize Threshold | If a product apparent width is larger than the oversize threshold, it is inducted on two trays. If it’s apparent width is larger than the tray length + oversize threshold, the product will not be inducted. |

| Disable Consecutive Trays | If true, 2 consecutive trays won’t tilt on the same chute even if the divert rule is evaluate successfully. This is used to simulate mechanical limitation of certain types of tilt tray sorter. |

| Product Count | Read only. Total number of products currently on the sorter. |

| Number of Occupied trays | Read only. A tray is occupied if a product is placed on the tray. |

| Exit Points | List of equipment to send product to when the conditions of the assigned Divert rule is met. See “Divert Rule”. |

| Allocation Points | List of positions on the sorter where trays are reserved for specific inductions. |

Trays

| Name | Description |

|---|---|

| Tray Height | Height in the units chosen when the project was created (metres or feet) of the trays. |

| Tray Width | Width in the units chosen when the project was created (metres or feet) of the trays. (orthogonal to the direction of travel) |

| Tray length | Length in the units chosen when the project was created (metres or feet) of the trays along the direction of travel. |

| Tray Gap Size | Gap between trays in the units chosen when the project was created. (metres or feet) |

| Number of Trays | Read only. Calculated based on the total Length, Tray Length and Tray Gap size properties. |

Sections

| Name | Description |

|---|---|

| Sections | List of section defining the path of the sorter. If Arc is zero the section is straight. If Arc is not zero, the section will be curved and defined by the Arc and length (metres) properties. |

| Total Length | Read only. Total length of the path of the sorter in the units chosen when the project was created (metres or feet). Calculated based on the section definitions. |

Visual

| Name | Description |

|---|---|

| Selectable | Set to ticked so this equipment can be selected. Untick if this equipment can not be selected |

| Layer | Assign a layer to this equipment to allow it to be hidden when the layer is not visible. Default to Background |

| Base | Allows a color and visible property to be set for the base |

| Trays | Allows a visible property to be set for the Trays |

| Tray number label start from 0 | A true or false value indicating whether the tray number label starts from zero or 1. |

Note: All trays are identified on the sorter by an index number.

This number is derived as follows:

trayIndex = Displayed tray number - 1